RKB’s latest acquisition for the Metallography Laboratory

A reliable, exigent, comprehensive, and well-organized quality control system is a must for producing high-performance rolling bearings.

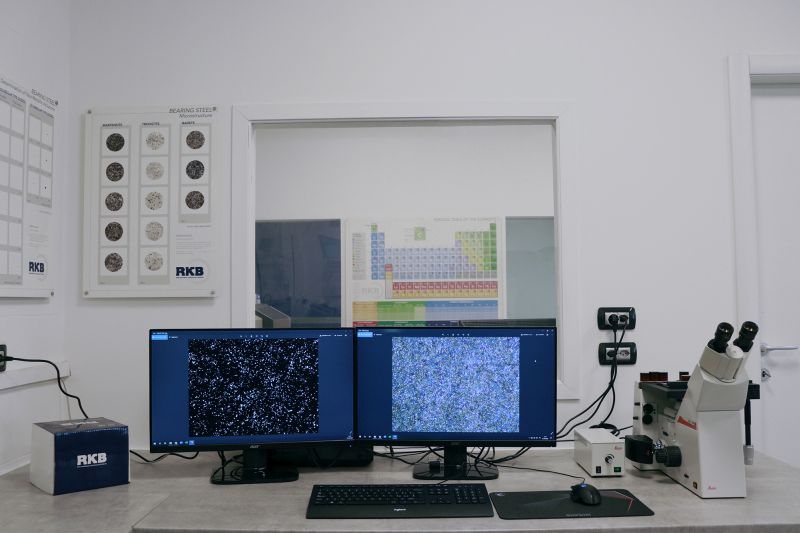

To sustain the previous statement, RKB continually invests in QC. Our latest acquisition is a new quality control system for the Metallography Laboratory from RKB HQ (Balerna, Switzerland), informed us Eng. Ciprian Radu. The system is formed from an inverted high-performance metallographic microscope, a high-resolution photo camera, and a series of specialized software modules from Leica Microsystems. The inspection in the metallographic field will now be conducted with increased speed, efficiency, and precision.

LAS X Core is a basic building block for RKB’s acquired software modules, as:

- LAS X Measurement, used for the measurement of the parameters, such as the length, area, diameter, angle, or perimeter of objects.

- LAS X Reticule displays digital reticules, such as grain size, lines, circles, and counting grids, on real-time images as electronic overlays for inspection, measurement, point counting, and comparison.

- LAS X 2D Analysis, where various objects and features, such as particles, voids, porosity, and more, can be analysed according to geometrical and morphological properties, as well as physical properties, like intensity or colour.

- LAS X Steel Expert helps to accurately and quickly rate the non-metallic inclusions to ensure its quality of steel, according to the latest international standard ISO 4967:2013.