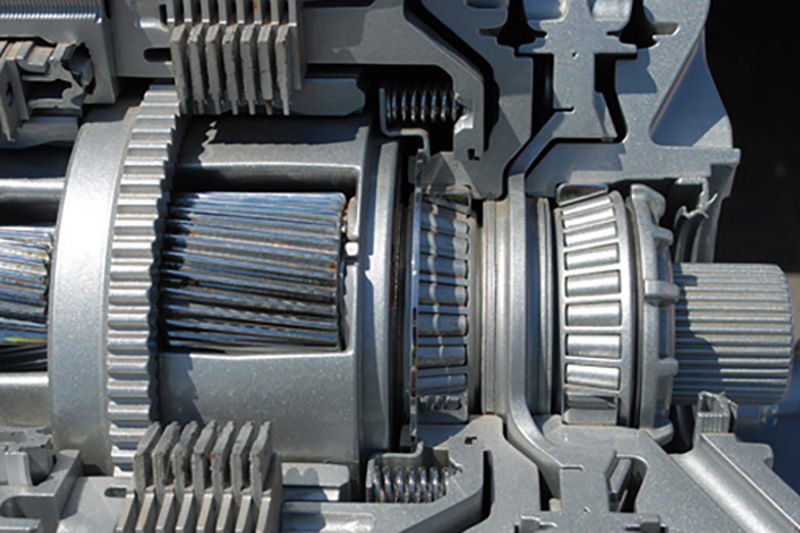

Double row full complement cylindrical roller bearings

Double row full complement cylindrical roller bearings feature solid inner and outer rings, as well as rolling elements properly guided between ribs. Due to their cageless design, they can host a larger number of rollers, which leads to higher load rating values. On the other side, they allow a maximum rotating speed lower than that of the caged design. Available in non-locating, semi-locating and locating design, these bearings represent the proper technical solution in several fields and applications.

Main types

-

Type NNC (SL01)

- Split outer ring with two integral ribs, clamped with a retaining ring

- Inner ring with three integral ribs

- Full complement (cageless) design for increased load carrying capacities

- Reduced maximum rotational speed compared to caged design

- Annular groove and lubrication holes in outer ring

- Optimized raceway geometry and roller profile

- Can be used in locating position

-

-

Type NNCL (SL02)

- Ribless outer ring

- Inner ring with three integral ribs

- Full complement (cageless) design for increased load carrying capacities

- Reduced maximum rotational speed compared to caged design

- Annular groove and lubrication holes in outer ring

- Separating ring between the two rows of rollers

- Optimized raceway geometry and roller profile

- Can be used in locating position

-

-

Type NNF (SL04)

- Outer ring with one central integral rib

- Split inner ring with three integral ribs, clamped with a retaining ring

- Full complement (cageless) design for increased load carrying capacities

- Reduced maximum rotational speed

- Annular groove and lubrication holes in outer and inner ring

- Optimized raceway geometry and roller profile

- Integrated rubber seals on both bearing sides to avoid contamination

- Available filled with grease

- Can be used in locating position

-

-

Type NNCF

- Outer ring with one integral side rib and

- retaining ring

- Inner ring with three integral ribs

- Full complement (cageless) design for increased load carrying capacities

- Reduced maximum rotational speed compared to caged design

- Optimized raceway geometry and roller profile

- Can be used in one direction locating position (semi-locating design)

- Available with annular groove and lubrication holes in outer or inner ring

-