Pre sales assistance

RKB offers its customers assistance and advisory services at each phase of the asset life cycle, from bearing design and selection to technical recommendations for equipment already in operation.

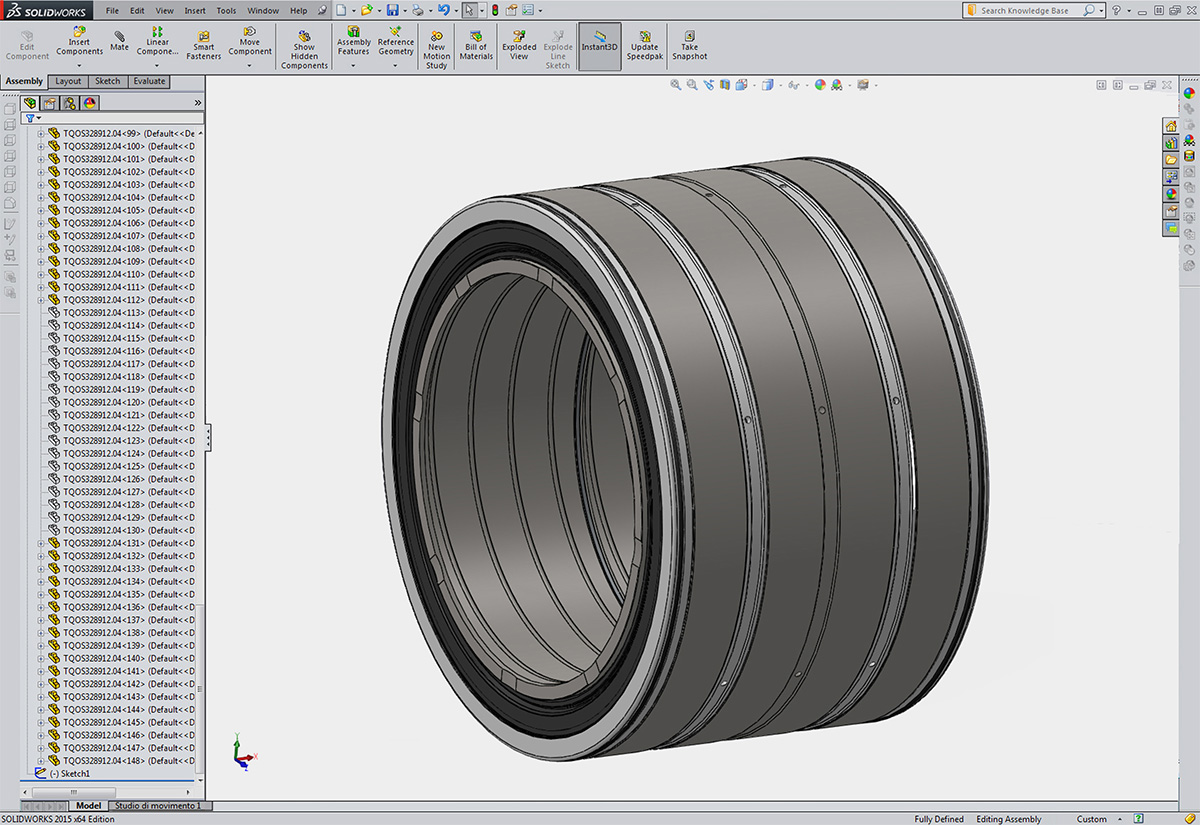

Bearing design

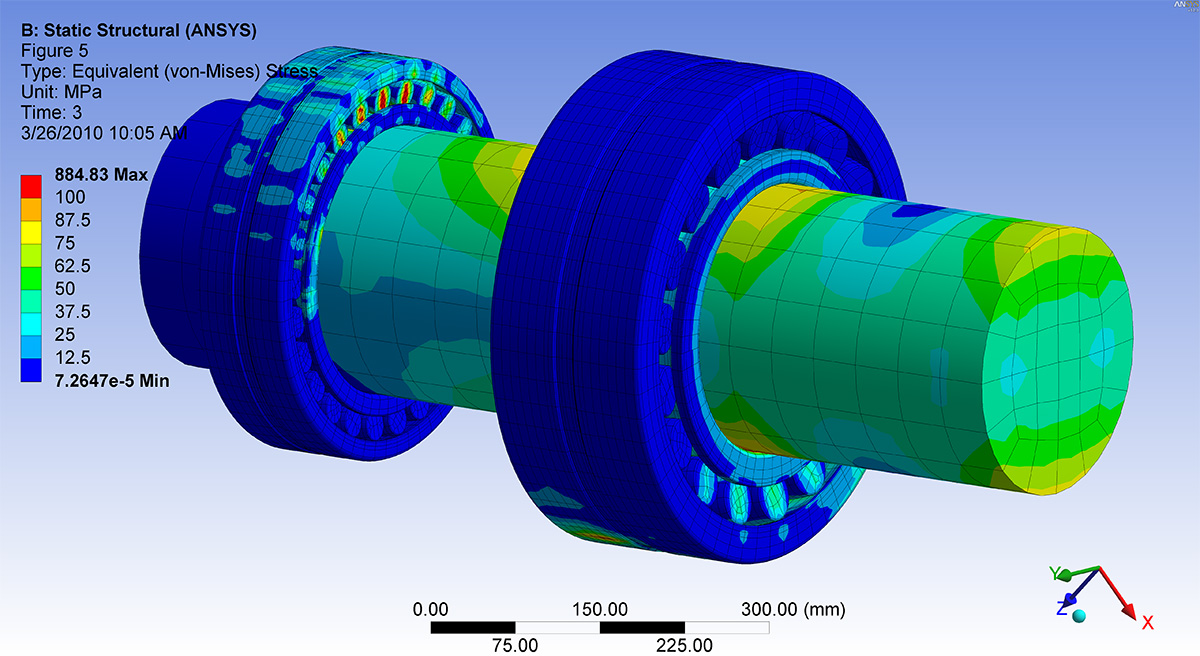

To optimize bearing performance, RKB makes extensive use of proprietary and commercial software systems, which strictly comply with the relevant international standards. Along with classic 2D drafting and 3D modelling tools for mechanical engineering, RKB can also count on a set of specifically developed evolutionary algorithms for mono- and multi-objective optimal design of bearing macro-geometry to maximize bearing life.

Finally, finite element (FEM) and semi-analytical (SAM) methods are selectively used to refine design solutions through advanced simulations.

Co-engineering activities

Whether it is a greenfield project or an existing application, RKB’s technical department can be actively involved in co-engineering and co-design with the customer’s technical office. Joint activities are mainly based on the chance of creating synergies between different domains of knowledge and expertise. In case of new applications, RKB can offer technical advice regarding:

- selection of bearing type, size, arrangement, fit with conjugate parts, internal clearance or preload, seals, and lubricant

- calculation of actual bearing loads, residual internal clearance or preload after mounting and in operation, bearing starting and operating torque, operating temperature, etc.

For machinery already in operation, RKB can provide value-added recommendations for:

- lubrication system and lubricants, to favor elastohydrodynamic conditions and decrease overall operating temperature

- regreasing intervals and grease amount to be used

- bearing handling and maintenance